Plain – no mount

Letters and logos are supplied with no mounting holes or hardware. View drawing

There are many mounting methods available for metal, plastic, and illuminated letters and logos, as well as plaques and changeable copy. Below, you will find the options available for each product line so that you can choose the one that will best fit your needs.

Letters and logos are supplied with no mounting holes or hardware. View drawing

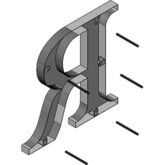

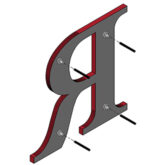

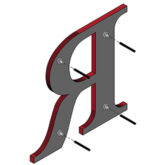

Backs of letters and logos, at least ¼” thick, are drilled and tapped to receive threaded studs for mounting to the wall. View drawing

Backs of 1/8″ thick letters and logos are supplied with welded stud bosses (to receive studs) or 1″ long welded studs for mounting to the wall. View drawing

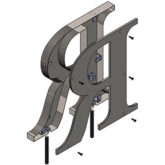

Top returns of letters and logos, at least 3/8″ thick, are drilled and tapped to receive threaded studs for mounting to the wall or rail. View drawing

Bottom returns of letters and logos, at least 3/8″ thick, are drilled and tapped to receive threaded studs for freestanding letters. Tie-backs (not supplied) are recommended for letters over 8″ high. View drawing

Top and bottom returns of letters and logos, at least 3/8″ thick, are drilled and tapped to receive threaded studs for mounting to the wall or rails. View drawing

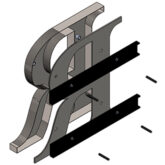

Backs of letters and logos, at least ¼” thick, are drilled and tapped to receive screws to secure letters onto two horizontal metal rails (bars or C-Channel) for mounting to the wall. View drawing

Stud mount is standard. Letters are drilled and tapped to receive threaded studs. Aluminum studs on aluminum letters and stainless steel studs on bronze letters. View drawing

Bottom stud mount is available on letters at least 4″ high and 3/8″ thick. Letters are drilled and tapped on the bottom returns. If letters are over 8″ high, a tie-back (not supplied) is recommended to secure the letter. View drawing

Minimum 3/8″ thick. Includes painted or anodized aluminum C-Channel rails. Letters over 8″ may require tie-back (not supplied). View drawing

Two rows of C-Channel painted or anodized aluminum rails are mounted with threaded aluminum bolts into in-line stud bosses. Letters are mounted by word. Maximum 96″ length. View drawing

For letters up to 4″ high, a single C-Channel painted or anodized aluminum rail is mounted with threaded aluminum bolts into in-line stud bosses. Letters are mounted by word. Maximum 96″ length. View drawing

A 90º angle bracket measuring 2″ x 2″ x 1/4″ is secured to bottom stud locations of letters. Tie-backs recommended for letters over 8″ (not supplied). Letters are mounted by word. Maximum 96″ length. View drawing

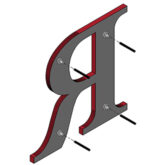

Bottom stud mount is available on letters 4″–24,” minimum 3/8″ thick. Letters are drilled and tapped on the bottom returns. Typical 3/16″–1/4″ wall thickness on hollow back letters/logos. View drawing

Top stud mount is available on letters at least 4″–24″, minimum 3/8″ thick. Letters are drilled and tapped on the top returns. Typical 3/16″–1/4″ wall thickness on hollow back letters/logos. View drawing

Thin metal straps recessed into the back and soldered to return. Stud boss welded to strap to receive threaded studs. The strap helps strengthen returns of the letter. This is the default mounting method for fabricated letters. Not for use with LED lighting systems as shadowing may occur. View drawing

Stainless L bracket with bosses to receive threaded studs is glued to inside return. Due to bracket size, a minimum 4″ high and minimum 1/2″ deep letter and stroke is required. View drawing

Threaded metal stud mount glued to the inside of the can. Thread size 10–24 for letters up to 12″ high. Thread size 1/4-20 for letters greater than 12″ and up to 24″. Smaller letters could also use this mount to receive pads with studs for a flush pad mount. Stroke and depth limitations may apply. View drawing

Stainless steel L brackets with stud bosses to receive threaded studs are attached to letter returns with truss head machine screws. This hardware allows metal cans to be removed from the Lexan backs after installation to service LEDs and wiring. Designed for Halo lit letters. View drawing

Steel backs are laser cut to fit within the inside of the return. This is not a perfect “puzzle” fit but is close. L brackets are glued to the inside return of the can. The steel is attached to the L bracket in one of two ways: 1. Loose tacked (welded), which is not removable. 2. Holes drilled through steel to allow for a pan head screw into the L bracket. Both methods have holes drilled for mounting studs. Backs are available raw, finished, or painted steel. Steel backs are recessed slightly to allow screw heads to be flush with the back of the letter. View drawing

Lexan backs are cut to fit within the inside of the return. This is not a perfect “puzzle” fit but is close. L brackets are glued to the inside return of the can. The Lexan is attached to the L bracket with stainless flat head screws. Lexan is flush with the back of the letter. Holes are drilled through Lexan to allow for mounting studs into L brackets. Lexan is available in clear or light diffusing. Optional detachable stud is available. Shown with optional white painted can interior. Up-charge for painting is 10%. View drawing

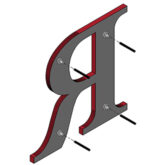

Holes and bosses in bottom to receive threaded studs. Letters over 12″ will require our Engineered Stud. Rounded letters will require some flattening. This method can only be selected on letters with a Lexan or steel back. Tie-backs (not included) are recommended for a safe installation on letters over 8″. View drawing

Holes and bosses in bottom/top to receive threaded studs. Backs and internal structure are included for additional support. Stud diameter may also vary per architect specifications. Rounded letters will require flattening. View drawing

Letters with no mounting hardware. Display Letters can be attached to the mounting surface with a combination of adhesive or double-faced tape – applied by the installer – based on surface and letter weight.

Stud blocks are solvent bonded to letter backs to receive a 10-24 stud. These blocks will require the letters to stand off the mounting surface approximately 3/8″–1/2″. Drilling patterns are required for this installation. View drawing

Thicker letters (minimum 1/4″ thick) can be drilled and tapped for stud installation. Specify if studs need to be in line for brick/block mortar joints or rails.

Stud blocks are solvent bonded to letter backs to receive a 10-24 stud or on 1/4″ or thicker material, drilled and tapped. These blocks will require the letters to stand off the mounting surface approximately 3/8″–1/2″. Studs are in line for mortar joints of brick or block. Drilling patterns are required for this installation.

Stud blocks are solvent bonded to letter backs to receive a 10-24 stud or on 1/4″ or thicker material, drilled and tapped. These blocks will require the letters to stand off the mounting surface approximately 3/8″–1/2″. Studs are in line for rails at the distance you specify. Drilling patterns are required for this installation.

Pads are plastic disks on the rear of the letters. Secure the letters to the wall using a split stencil pattern or spacing tape guide and silicone adhesive. Adjustable or flush pads available upon request.

Combination of studs and pads. Stud through a pad on the top portion of each letter, pads only on the bottom portion of each letter. Mounting procedure is the same as a Stud Mount with the addition of securing pads to the mounting surface with adhesive. Studs can be aligned in line for brick or block mortar upon request. Laser-cut letters (minimum 1/4″ thick) can be drilled and tapped to receive studs to allow for a flush mounting. Drilling patterns are required for this installation.

Combination All mounts have stud through a pad on the top and bottom portion of each letter. Mounting procedure is the same as a Stud Mount. Studs can be aligned in line for brick or block mortar upon request. Laser-cut letters (minimum 1/4″ thick) can be drilled and tapped to receive studs to allow for a flush mounting. Drilling patterns are required for this installation.

Double-faced Tape mount comes with either partial or fully covered backs with a VHB, double-faced tape. Volume of tape is based on letter size and gauge. Heavier letters may require tape and adhesive (such as epoxy on acrylic) to properly secure letters. VHB tape is designed for interior, flat, drywall installations.

Letters come with no mounting hardware. Customer provides own hardware.

Letters are supplied with plastic blocks that are threaded to receive included studs. Drilling patterns are required for this installation. View drawing

Letters are supplied with plastic pads on the backs of letters. Secure the letters to the wall using a split stencil pattern or spacing tape guide and silicone adhesive. Adjustable or flush pads available upon request.

Letters have pads at the bottom and pad/stud combinations at the top of the letter. Specify if studs need to be in line for brick or block wall mortar joints. Not for letters under 6″.

Letters have studs through pads on all mounts. Specify if studs need to be in line for brick or block wall mortar joints. Not for letters under 6″.

Letters have L brackets glued to the inside returns of letters. These brackets flare outward from the back and have a hole to put a screw through and into your mounting surface.

Letters come with no mounting hardware. Customer provides own hardware.

Letters are supplied with plastic blocks that are threaded to receive included studs. Drilling patterns are required for this installation. View drawing

Letters are supplied with plastic pads on the backs of letters. Secure the letters to the wall using a split stencil pattern or spacing tape guide and silicone adhesive. Adjustable or flush pads available upon request.

Letters have pads at the bottom and pad/stud combinations at the top of the letter. Specify if studs need to be in line for brick or block wall mortar joints. Not for letters under 6″. Drilling patterns are required for this installation.

Letters have studs through pads on all mounts. Specify if studs need to be in line for brick or block wall mortar joints. Not for letters under 6″. Drilling pattern required on this installation.

Letters with no mounting hardware. Display Letters can be attached to mounting surface with a combination of adhesive or double-faced tape – applied by the installer – based on surface and letter weight.

Stud blocks are solvent bonded to letter backs to receive a 10-24 stud. These blocks will require the letters to stand off the mounting surface approximately 3/8″–1/2″. Drilling patterns are required for this installation. View drawing

Thicker letters (minimum 1/4″ thick) can be drilled and tapped for stud installation. Specify if studs need to be in line for brick/block mortar joints or rails.

Combination of studs and pads. Stud through a pad on the top portion of each letter, pads only on the bottom portion of each letter. Mounting procedure is the same as a Stud Mount with the addition of securing pads to the mounting surface with adhesive. Studs can be aligned in line for brick or block mortar upon request. Laser-cut letters (minimum 1/4″ thick) can be drilled and tapped to receive studs to allow for a flush mounting. Drilling patterns are required for this installation.

Pads are plastic disks on the rear of the letters. Secure the letters to the wall using a split stencil pattern or spacing tape guide and silicone adhesive. Adjustable or flush pads available upon request.

Double face tape mount comes with either partial or fully covered backs with a VHB, double-faced tape. Volume of tape is based on letter size and gauge. Heavier letters may require tape and adhesive (such as epoxy on acrylic) to properly secure letters. VHB tape is designed for interior, flat, drywall installations.

Letters are secured to walls with screws – type and size to match letter weight and mounting surface type. Holes pre-drilled into letter backs by installer. Screws pass through plastic and into the mounting surface. Washers and/or anchors may be required.

Letters are secured to raceways or rails (containing wires) with screws – type and size to match letter weight and mounting surface type. Holes pre-drilled into letter backs by installer. Screws pass through plastic and into the raceway or rail. Washer and/or wall anchors may be required.

Letters designed to create a halo effect (when lit with LEDs) are typically mounted to walls with studs and spacers to stand off the wall, thus creating a halo. Typical stand-off is around 1-1/2″ but can vary based on desired halo look and mounting surface color or sheen. Illuminated letters provided with LEDs and a UL Listing will be provided with installation and wiring instructions as well as required special considerations regarding any electrical work – based on local and national electric (NEC) and UL codes or requirements.

Plaques with no mounting hardware that can be attached to mounting surface with a combination of adhesive or double-faced tape – based on surface and plaque weight.

Back of plaque is drilled and tapped to receive threaded studs. Studs are pressed into pre-drilled wall holes and secured with adhesive and/or anchors – based on the wall type and letter weight. Studs can be aligned in-line for brick or block mortar upon request. View drawing

Machine screws, passing through plaque holes, with or without decorative rosettes. Screws are either bonded into wall holes with adhesive or a combination of adhesives and anchors – based on wall and plaque size and weight. View drawing

Machine screws with toggle, passing through plaque holes, with or without decorative rosettes. Screws are then tightened to expand toggle in a hollow wall cavity. View drawing

Wood screws, passing through plaque holes, with or without decorative rosettes. Screws are screwed into a wooden wall surface or bonded with adhesive to further secure. View drawing

Machine screws are inserted through 5/16″-thick black anodized stakes into the back of the plaque. Maximum plaque size is 12″ x 8″ for one stake or 20″ x 8″ for two stakes. Available in heights of 24,” 36″ and 48″.

Cast as part of an aluminum or bronze plaque, the post cap mount is designed to fit on 1-½,” 2″ or 3″ ID schedule 40 posts. Available on almost any custom plaque – single or double-sided – up to 30″ x 30″. Post sold separately. View drawing

Flat changeable Pronto or Moon-Glo letter track is either glued or screwed to walls. The track is designed to allow letters to be removed from the face with a Change Arm. Track spacing is based on letter size and mounting surface.

Flat changeable Pronto or Moon-Glo track is either glued to panels or attached with nylon rivets. The track is designed to allow letters to be removed from the face with a Change Arm. Track spacing is based on letter size and mounting surface.